Manufacturing has never been more complex. Companies are under pressure to deliver faster, reduce costs, comply with stricter regulations, and adapt to volatile supply chains. At the same time, every manufacturer knows that no two production environments are alike. Processes that work in automotive look very different from those in aerospace, pharmaceuticals, or consumer goods.

This is where many manufacturers hit a roadblock with off-the-shelf ERP or MES systems. While these platforms offer a broad set of functions, they often impose rigid, one-size-fits-all workflows. The result? Businesses end up changing their operations to fit the software, instead of having software that reflects the way they actually work.

To bridge this gap, some manufacturers explore custom manufacturing software — solutions tailored to their exact needs. The big question is how to approach it: build from scratch, customize an existing ERP, or take a platform-based middle path that balances speed, flexibility, and cost.

What Is Custom Manufacturing Software?

Custom manufacturing software is purpose-built to reflect the unique workflows of a manufacturing business. Unlike generic ERP or MES systems that come with pre-defined templates, custom solutions are designed around the manufacturer’s own products, processes, and constraints.

For example, a pharmaceutical company may need production scheduling that aligns with material shelf-life and regulatory audits. An aerospace manufacturer might require a multi-level bill of materials (BOMs) with variant management and traceability for every component. A food and beverage company may need integrated recipe management, batch tracking, and quality checkpoints.

The goal of custom manufacturing software is simple:

- Adapt to the business, instead of forcing the business to adapt.

- Provide flexibility to evolve as production models, compliance rules, and customer expectations change.

- Offer a competitive edge by digitizing workflows that are unique to the company.

In short, while off-the-shelf systems aim for breadth, custom software aims for depth — addressing the precise needs of a manufacturer’s operations.

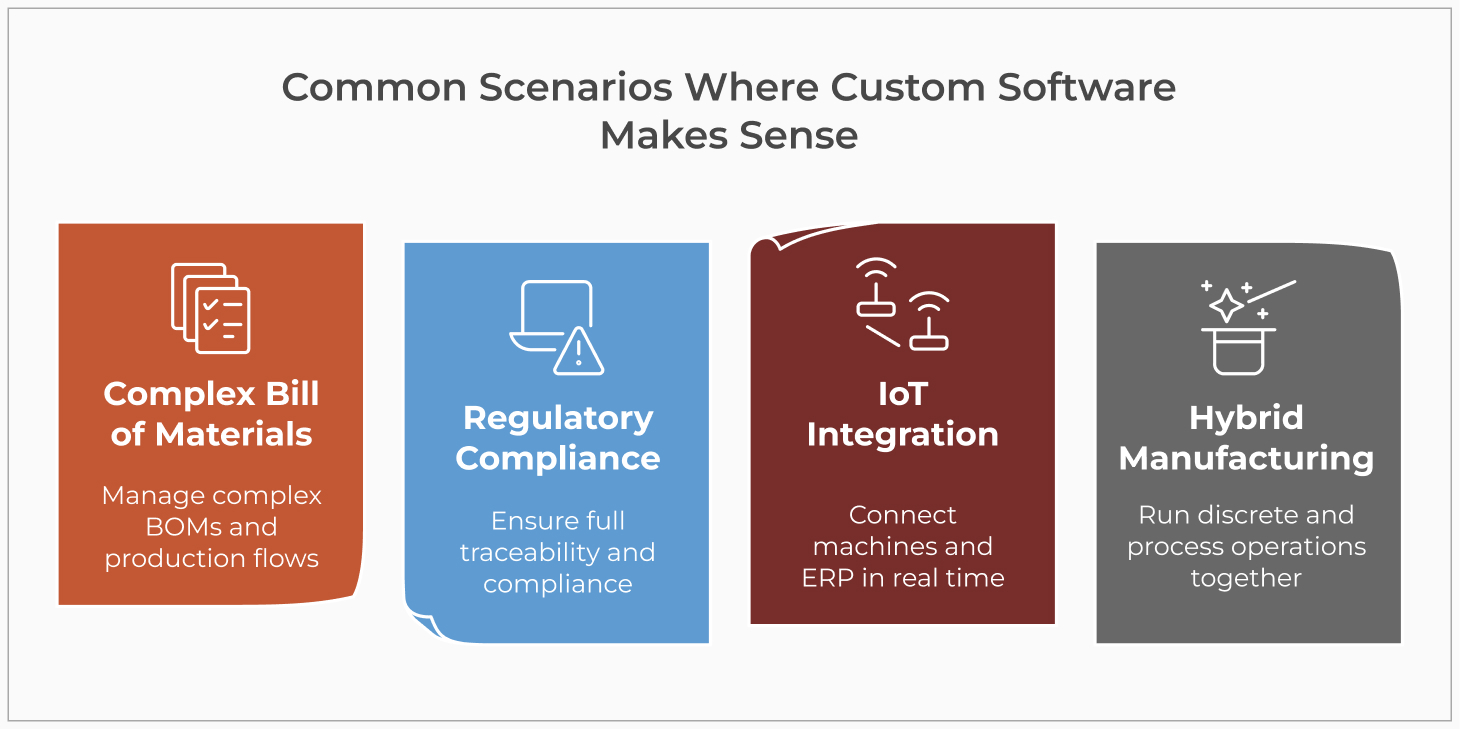

Common Scenarios Where Custom Software Makes Sense

Many manufacturers run into situations where standard ERP systems start to show their limits. Here are some of the most common scenarios where custom software makes sense.

1. Complex Bills of Materials (BOMs) and Routing

Many manufacturers deal with products that have hundreds or thousands of components, variant configurations, or multi-tier subassemblies. Off-the-shelf ERP defaults struggle with this level of granularity.

- Example: An automotive supplier producing the same part in 20 variations for different OEMs needs flexible BOM management and dynamic routing.

2. Regulatory Compliance Workflows

Industries like pharma, aerospace, and food demand strict compliance and auditability. Generic ERPs typically handle compliance superficially, leaving businesses to plug gaps with spreadsheets or manual processes.

- Example: A pharmaceutical company must enforce FDA compliance at every batch stage — from sourcing to labeling, something most ERP templates weren’t designed for.

Modern manufacturing floors rely on sensors, PLCs, and IoT devices that generate real-time data. Integrating these into rigid ERP workflows is often clunky or impossible.

- Example: A factory wants machine downtime alerts from PLCs to automatically trigger maintenance work orders — a level of integration rarely achievable with plug-and-play ERPs.

Some businesses operate across discrete and process manufacturing simultaneously (e.g., food companies producing packaged goods but also mixing raw ingredients). Off-the-shelf ERPs are usually optimized for one manufacturing mode, not both.

- Example: An apparel company manufacturing shoes (discrete) while dyeing fabrics (process) needs a system that can handle both natively.

The takeaway is simple: whenever the software has to bend unnaturally to accommodate the business, manufacturers are better served by solutions that are built around their unique realities. That’s where custom platforms show their true value.

The Dilemma: Build from Scratch vs. Customize ERP

Once a manufacturer decides that off-the-shelf software won’t cut it, the next question is how to approach custom development. Two common paths emerge — and both come with challenges.

Building from Scratch

Some organizations consider developing their own manufacturing software from the ground up. While this promises complete control, it often proves impractical:

- High cost and long timelines — Developing even basic features like inventory, orders, and costing can take years.

- Reinventing the wheel — Many of these functions are already solved problems. Building them again adds little value.

- Maintenance burden — Once built, the system needs constant updates to keep up with compliance, integrations, and security.

For most manufacturers, building from scratch quickly becomes a costly and risky endeavor.

Customizing Commercial ERP

On the other end of the spectrum, many turn to established vendors like SAP, Oracle, or Infor and attempt to heavily customize their ERP. This approach offers a ready foundation, but it comes with its own limitations:

- Vendor lock-in — Customizations are tied to the vendor’s roadmap, pricing, and upgrade cycles.

- High costs — Licensing fees combined with customization projects often exceed initial budgets.

- Rigid templates — Even after customization, workflows often remain constrained by the vendor’s core design.

The result? Manufacturers either spend millions adapting ERP systems to their business, or compromise by adapting their business to the ERP. Neither path delivers the flexibility most companies truly need.

This is why many manufacturers look for a middle path, a platform that provides ready-made building blocks but still allows deep customization. And this is where Apache OFBiz™ comes into play.

The Middle Path: Custom Manufacturing Software with Apache OFBiz

For manufacturers who want the flexibility of custom software without the risk and expense of building everything from scratch, the best option is a platform-based approach.

Instead of reinventing core business functions, companies start with a proven platform and then extend or customize it to reflect their unique processes. This middle path balances speed, flexibility, and cost.

Why Apache OFBiz Fits the Bill

Among open-source platforms, Apache OFBiz™ is uniquely suited for this role. Backed by the Apache Software Foundation, Apache OFBiz combines ready-to-use enterprise modules with the flexibility to build manufacturing-specific solutions.

- Modular Business Suite – Prebuilt modules for order management, procurement, warehouse, and manufacturing, mean you don’t waste time rebuilding basics.

- Manufacturing Execution and Planning (MEPS) Capabilities – Multi-level BOMs, routing, MRP, work orders, costing, compliance, and quality checks can all be configured within Apache OFBiz. For example, in aerospace, Apache OFBiz enables traceability across complex assemblies, while in FMCG, it supports agile inventory management to keep up with seasonal demand.

- Scalability – From a single site to global multi-plant operations, Apache OFBiz grows with your business.

- Open-Source Freedom – No vendor lock-in, transparent governance, and continuous innovation through the Apache community.

- HotWax Expertise – With decades of experience, HotWax Systems customizes Apache OFBiz to deliver industry-specific solutions — from aerospace compliance to FMCG agility.

This combination gives manufacturers a head start with a robust foundation, while retaining the freedom to design software that fits their exact workflows.

Conclusion

Manufacturers know that software can no longer be one-size-fits-all. Off-the-shelf ERP and MES systems may cover the basics, but they rarely capture the unique complexity of modern production environments. Building custom software from scratch is risky and expensive, while over-customizing a commercial ERP leads to vendor lock-in and spiraling costs.

The answer lies in the middle path: a platform that provides ready-made building blocks while giving manufacturers the freedom to tailor workflows, integrate shop-floor systems, and evolve with changing business needs.

This is exactly what Apache OFBiz™ delivers. Backed by the Apache Software Foundation and supported by experienced partners like HotWax Systems, Apache OFBiz offers a stable, open-source foundation that can be configured into a powerful custom manufacturing solution, one that adapts to your processes instead of forcing you to adapt to the software.

To accelerate this journey, HotWax Systems has developed the HotWax Accelerator — a prebuilt layer on top of Apache OFBiz with modern user interfaces, enterprise-grade search, built-in analytics, and ready integrations. This means manufacturers don’t start from scratch, but from a head start, reducing implementation time while still retaining the freedom to customize deeply.

Ready to explore how Apache OFBiz and HotWax Accelerator can serve as the foundation for your custom manufacturing software? Connect with HotWax Systems today and see how we can help design a solution that fits your operations, industry, and future growth.