Many manufacturers focus on what needs to be built, while the question of how it will be built remains loosely defined. Product structures are carefully documented, but the actual production flow is often left to experience, verbal instructions, or scattered spreadsheets. This approach may work at a small scale, but as operations grow, it quickly leads to delays, idle resources, rework, and inconsistent output.

Without a clearly defined production flow, teams struggle to answer fundamental questions. Which operation comes first? Which machine should be used? How long will each step take? What will it cost?

Routing addresses this gap. Apache OFBiz provides a structured way to define Routings and Routing Tasks that show exactly how a product moves through production. By capturing operation sequences, assigning resources, and tracking time and cost, Apache OFBiz transforms manufacturing execution into a predictable and scalable process.

Once the Bill of Materials for a product, Routing translates it into an executable production flow. This blog focuses on the concept and role of Routing in Apache OFBiz.

What is Routing in Apache OFBiz

Routing in Apache OFBiz defines how a product is manufactured (processed, assembled, and transformed into a finished product) by organizing production work into a structured, sequential flow. It represents the operational blueprint that guides how materials move through each stage of production. By enforcing a defined order of operations, Routing ensures consistency, efficiency, and control across manufacturing activities.

What Routing Provides in Apache OFBiz

Routing Task Association

A Routing links multiple Routing Tasks in a defined sequence. This sequence determines the order in which operations are executed during production.

Routing Product Link

A Routing can be linked to a finished product, indicating the item that is produced once all associated Routing Tasks are completed.

What is a Routing Task

A Routing Task represents a single, well defined operation within a Routing. Each task corresponds to a specific stage of production and captures how work is performed at that stage.

What Routing Tasks Provide in Apache OFBiz

Routing Task Cost

Routing Tasks support detailed cost configuration for individual operations. Fixed and variable costs can be captured at the task level for accurate production cost calculation.

Delivered Product

A Routing Task can define a deliverable product, representing the output produced after completing that specific operation. This is especially useful for sub assemblies and intermediate production stages.

Example: Routing and Routing Tasks in Skateboard Manufacturing

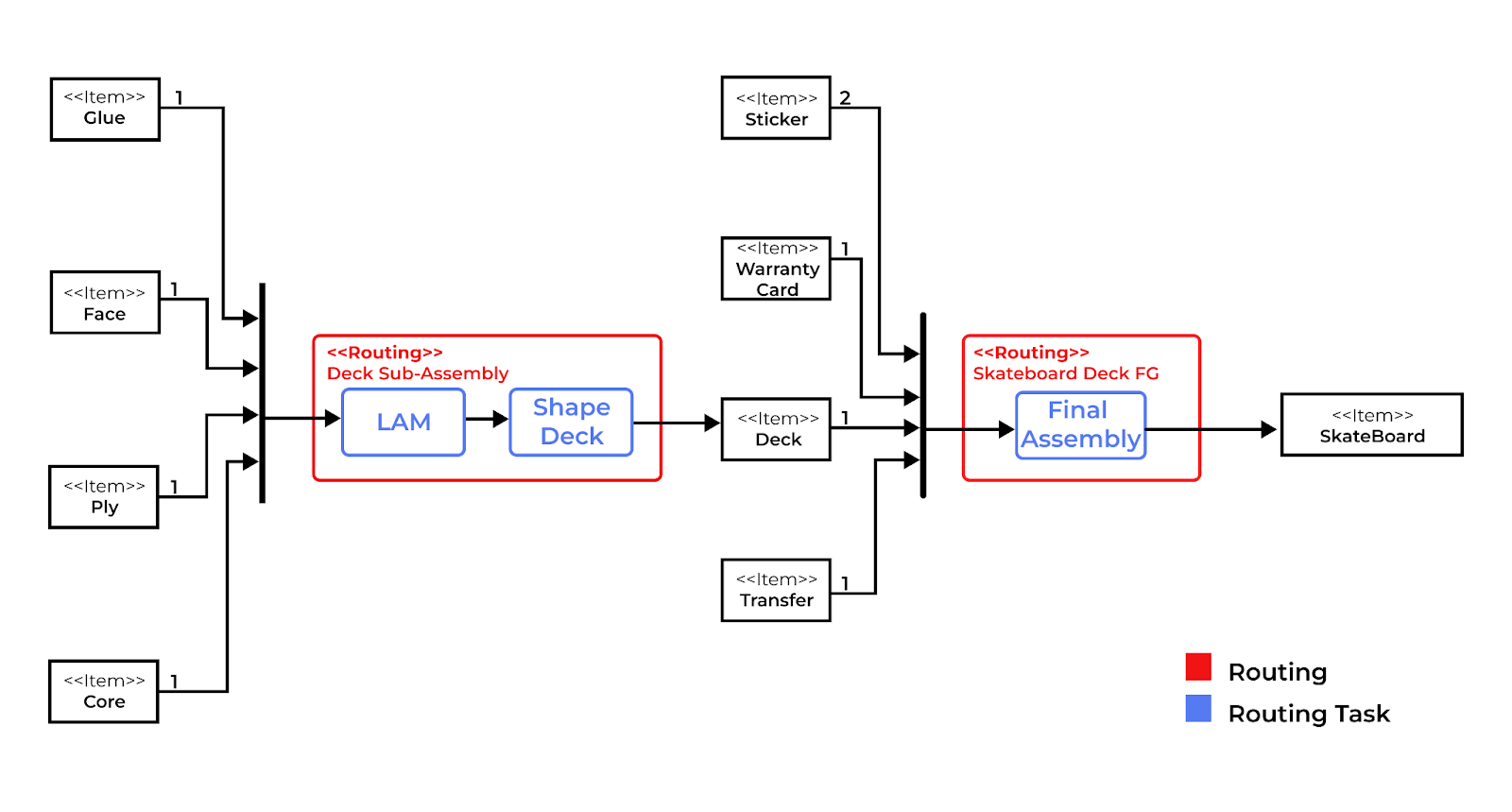

Fig.1- Flow diagram explaining BOM, Routing and Routing task of a skateboard.

A skateboard, as a finished product, is made up of multiple components and sub-components, each requiring specific Routings and Routing Tasks. These tasks define the sequence of operations essential to the final assembly.

The skateboard production process begins with creating the deck, the core component of the skateboard. The deck is formed by combining glue, face, ply, and core, processed under the Deck Sub-Assembly Routing.

Routing 1- Deck Sub-Assembly

Routing Tasks:

- LAM (Lamination) – Bonds all layers using glue to form the deck structure.

- Shape Deck – Refines the deck to its final design

Once the deck is complete, it moves to the Skateboard Deck FG Routing, where the Final Assembly task is performed. Here, the deck is combined with stickers, a warranty card, and transfer elements to complete the finished skateboard.

Routing 2- Skateboard Deck FG

Routing Tasks:

- Final Assembly – Combines the deck with stickers, a warranty card, and transfer elements to create the finished skateboard.

Why Routing and Routing Tasks Matter in Apache OFBiz

Even small inefficiencies, such as unclear task order or unassigned resources can lead to delays, rework, and higher costs. Routing and Routing Tasks provide a structured framework that ensures production follows a consistent and predictable flow.

Key Benefits for Manufacturers

- Clear and Standardized Production Flow

Every product follows a defined sequence of operations, reducing ambiguity and reliance on informal knowledge. - Improved Resource and Time Utilization

Machines, labor, setup times, run times, and working calendars can be aligned to minimize idle time and bottlenecks. - Accurate Costing and Reliable Scheduling

Actual production costs are calculated after each production run, covering both item level costs and routing level costs. Production durations and procurement lead times are also calculated, giving manufacturers clear visibility into material arrival and production completion timelines. - Consistent Quality and Full Traceability

Each operation is documented and traceable, ensuring consistent output and easier root cause analysis.

Routing in Apache OFBiz is more than a technical setup; it is the foundation for efficient, scalable, and high quality manufacturing operations.

Setting Up Routing in Apache OFBiz

This section outlines the key steps for setting up Routing in Apache OFBiz, focusing on the overall process.

Step 1: Create the Routing

Create a Routing for the finished product or any required sub assemblies. This defines the overall production flow and serves as the framework for all manufacturing operations.

Step 2: Define Routing Tasks

Create Routing Tasks to represent each major operation in the manufacturing process. Each task corresponds to a distinct stage, such as processing, assembly, or finishing.

Step 3: Associate Routing Tasks with the Routing

Link the Routing Tasks to the Routing in a defined sequence. This ensures production activities follow a consistent and controlled flow.

Step 4: Link the Routing to the Product

Associate the Routing with the relevant product or sub assembly. This enables Apache OFBiz to apply the Routing during production planning and execution.

Step 5: Validate and Activate the Routing Structure

Review the complete setup to ensure all tasks are correctly sequenced and linked. Once validated, the Routing becomes available for production scheduling, resource planning, and cost calculation.

For a detailed, step by step walkthrough with configuration screens and practical examples, refer to the in depth tutorial on Apache OFBiz (Confluence) here A practical guide to setup Routing in Apache OFBiz for Manufactures in 4 easy Steps.

Conclusion

Routing converts product definitions into executable production logic. By translating the Bill of Materials into a defined sequence of operations, Apache OFBiz ensures that manufacturing follows a controlled and repeatable process.

This foundation becomes especially important when moving into Material Requirement Planning. Accurate MRP depends not only on knowing what materials are required, but also on when and how production activities occur. Well defined Routings provide the timing, sequencing, and cost inputs that allow MRP calculations to produce reliable results.

In the next document, we build on this foundation by exploring how Apache OFBiz uses Routing and the Bill of Materials together to drive Material Requirement Planning. This connection shows how production structure directly influences planning accuracy, inventory decisions, and overall manufacturing readiness.

From advanced Routing configurations to automated routing tasks sequencing, we help businesses refine production processes for greater efficiency and scalability. With tailored solutions, HotWax Systems ensures your manufacturing workflows run smoothly and adapt to your specific needs.

Looking to customize and scale Apache OFBiz for your manufacturing process? Partner with HotWax Systems for a solution tailored to your needs.