In the face of fluctuating customer demand, tight deadlines, and complex production dependencies, manufacturers need more than just a basic inventory or scheduling tool—they need a system that brings everything together. That’s where Manufacturing Resource Planning (MRP) software comes into play.

Unlike the earlier generation of tools that focused solely on material requirements, today’s MRP software (also known as MRP II) offers a more integrated approach. It helps manufacturers calculate precise material needs using the Bill of Materials (BOM), track real-time inventory, factor in supplier lead times, manage shop floor activities, and even plan labor and machine capacity. This blog explores what MRP software truly is, its key modules and features, how it benefits manufacturers, and what to consider when choosing the right solution for your business.

MRP I vs. MRP II

The term MRP originally stood for Material Requirements Planning—a system developed in the 1960s to ensure that the right materials were available at the right time for production. This was later referred to as MRP I. MRP I focused exclusively on materials—it pulled data from sales forecasts, inventory, and BOMs to generate procurement and production schedules. However, it lacked the ability to factor in broader production resources like labor, equipment, and shop floor constraints.

This limitation gave rise to Manufacturing Resource Planning (MRP II) in the 1980s. MRP II expanded on the logic of MRP I and brought in additional dimensions such as capacity planning, work center scheduling, job costing, shop floor control, and more. It is a more comprehensive system that integrates with other business functions—like finance and human resources—and provides a closed-loop planning environment.

When we refer to “MRP software” in this blog, we’re specifically referring to MRP II software.

What is MRP Software?

MRP software is an integrated system that helps manufacturers plan, schedule, and manage various aspects of their production processes. It connects core manufacturing functions, like materials planning, inventory control, production scheduling, labor, and capacity management—into one centralized platform.

While early MRP systems were primarily concerned with material requirements (MRP I), modern MRP software, based on MRP II principles, goes beyond just raw material planning. It incorporates real-time data from across departments to create a holistic view of manufacturing operations and support data-driven decision-making.

By leveraging accurate inventory data, bill of materials, and demand forecasts, MRP software helps determine what needs to be produced, when, and with which resources. It simplifies purchase requisitions, optimizes production sequences, and ensures timely delivery—minimizing both overstocking and stockouts.

In short, MRP software brings visibility, control, and agility to the manufacturing floor, enabling manufacturers to stay competitive in a fast-changing environment.

Key Features of the MRP Software

These are the core building blocks of the Manufacturing Resource Planning Software, each responsible for a critical part of the manufacturing process.

- Material Requirements Planning

The MRP engine is the core of any MRP software. It calculates what materials are needed, in what quantities, and when they are required to meet production demand. By evaluating Bills of Materials (BOMs), current inventory levels, open production and sales orders, and supplier lead times, the MRP engine generates time-phased requirements for raw materials and components. This ensures materials are available just in time for production—avoiding both shortages and excess inventory—and enables proactive procurement and production planning to meet delivery commitments with confidence. - Production Planning and Scheduling

Production Planning and Scheduling is a critical component of MRP software, enabling businesses to align their manufacturing operations with real-world constraints. This module helps create realistic and efficient production plans by considering factors such as machine and labor availability, production capacity, material readiness, and order priorities. It ensures that manufacturing tasks are sequenced and timed optimally to minimize bottlenecks, reduce idle time, and meet delivery deadlines.

A well-implemented planning and scheduling system also facilitates quick rescheduling in response to unexpected events—like machine breakdowns or urgent orders—allowing production teams to stay agile while maintaining overall throughput and efficiency. - Inventory Management

Inventory Management allows businesses to track and manage their inventories in real time. It provides visibility into stock levels, locations, and usage, enabling accurate inventory control and timely replenishment.

Robust inventory management is critical to efficient manufacturing operations. A well-designed MRP software tracks inventory across its entire lifecycle—right from the moment raw materials enter the facility, through various stages of work-in-progress, to their final use in finished goods, and ultimately until those goods leave the warehouse.

MRP software enables real-time tracking of stock on hand, shelf inventory, shop floor inventory, and material reserved for both planned production and confirmed sales orders. It also calculates “available to promise” quantities, which is key for accurate customer commitments.

Advanced systems even support serialized inventory tracking, allowing traceability of exactly which serialized components went into which finished products—vital for compliance, warranty, and recall management. This level of granular control ensures optimal material utilization, reduces waste, and improves on-time production and delivery performance. - Shop Floor Control

Shop floor management in MRP software revolves around seamless execution and real-time control of manufacturing activities. Work order execution becomes streamlined as operators receive clear, system-generated instructions on tasks, materials, and routing steps.

The software ensures that human and machine resources, as well as raw materials, are allocated efficiently based on availability and priority. It provides real-time visibility into machine status, active work orders, and progress at each stage of production, enabling swift responses to issues or delays. With built-in traceability, MRP software tracks every material, lot, or serialized component used on the shop floor, ensuring full accountability and compliance across the production lifecycle. - Quality Management

MRP software plays a key role in quality management by embedding quality control checkpoints directly into the production workflow. After production, the system can be configured to require inspection of finished goods before they are accepted into inventory. Only once items pass inspection—based on predefined quality parameters—are they marked as approved and added to the inventory stock. This ensures that only quality-checked goods are available for sale or further processing.

Additionally, MRP software can log inspection results, track defect rates, and link quality data to specific work orders, batches, or operators—enabling root cause analysis, continuous improvement, and compliance with industry standards. - Procurement Management

Procurement management in MRP software is tightly integrated with the MRP engine to ensure timely and accurate purchasing. Based on material requirements generated by MRP, the system helps create Purchase Orders (POs) with minimal manual input. It factors in supplier agreements, including predefined pricing, lead times, and terms, ensuring cost-effective procurement. Once goods are received against a PO, the inventory is updated in real time, maintaining accurate stock levels.

The system also supports the full procure-to-pay cycle—enabling invoice creation, matching it with received quantities and agreed pricing, and facilitating timely vendor payments—all while maintaining complete audit trails.

Benefits of MRP Software

While modules and features describe what an MRP II system does, the benefits explain why it matters. These are the strategic advantages that manufacturers gain from implementing MRP software across their operations:- Better Cross-Departmental Coordination

MRP software breaks down silos by providing a unified platform where all departments—from production and procurement to inventory and sales—operate on shared, real-time data. When everyone sees the same information—such as material availability, order priorities, or production status—decisions become faster, more accurate, and more aligned. This reduces miscommunication, prevents duplication of effort, and fosters greater accountability across the organization, driving smoother operations and better strategic execution.

- Bottleneck Prevention

MRP Software identifies potential production bottlenecks before they impact output. By providing early warnings on capacity constraints, inventory shortages, or resource clashes, it enables planners to make proactive adjustments. This ensures smoother operations, fewer delays, and improved flow across the manufacturing process.

- Enhanced Customer Satisfaction

Reliable production and delivery timelines lead to better customer experiences. MRP Software ensures that orders are fulfilled accurately and on schedule by aligning every stage of production with the real-time data. With fewer delays and more predictable outcomes, businesses can meet customer expectations consistently and strengthen their brand trust.

- Compliance and Audit Readiness

With built-in traceability and quality control, MRP software keeps detailed records of every material, batch, and production step.This not only helps ensure regulatory compliance but also simplifies internal and external audits. Manufacturers can quickly retrieve documentation and prove adherence to standards, reducing the risk of penalties or product recalls.

- Cost Reduction

MRP software directly contributes to cost savings by improving inventory accuracy, reducing overproduction, and minimizing downtime. With precise material planning and better visibility into shop floor operations, businesses can lower inventory carrying costs, cut back on emergency purchases, and reduce waste from production errors. These efficiencies translate into significant savings over time. - Higher ROI from Digital Transformation

MRP Software lays the foundation for a connected, data-driven manufacturing environment. It integrates planning, execution, and monitoring into a unified workflow, enabling continuous improvement and digital agility. As companies modernize their operations, MRP software delivers measurable ROI through better decision-making, improved performance, and scalable growth.

How to Choose an MRP Software

Selecting the ideal MRP II software means assessing both current functionality and future adaptability. Below are the key factors to keep in mind:

- Scalability

Choose a system that can grow with your business—whether that means handling increased production volumes, a larger product catalog, or coordinating operations across multiple facilities. - Customization

Look for software that supports deep customization, so you can tailor workflows, modules, and business rules to fit your processes—without sacrificing future upgradability or maintainability. - Integration Capabilities

A good MRP Software should integrate seamlessly with your existing ERP, CRM, accounting platforms, and other key business systems to create a unified digital ecosystem and eliminate data silos. - User-Friendliness

Look for an easy to use and intuitive user interface that minimizes training effort and encourages widespread adoption across different teams. - Vendor Support and Community

Consider the strength of vendor support, availability of clear documentation, and presence of a helpful user community—crucial for both proprietary and open-source tools. - Total Cost of Ownership

Go beyond license fees. Consider implementation, customization, training, support, and ongoing maintenance when calculating the total cost. A solution with a lower initial price may end up more expensive if hidden costs emerge over time.

Open Source vs. Proprietary MRP Software

When choosing an MRP software, businesses often weigh the flexibility of open-source systems against the convenience of proprietary platforms. Each has its own distinct strengths, and the right choice depends on your organization’s technical capabilities, customization needs, and long-term goals.Open Source MRP Software

Below are some key strengths of open-source MRP software.- Flexibility and Customization

Open-source software is built on publicly available source code, thus making it highly customizable. Businesses can tailor the system to match their exact manufacturing workflows, industry requirements, and operational logic—something that’s difficult or even impossible with proprietary tools. - Fostering Innovation

As open-source platforms allow full control over the codebase, they naturally foster a culture of innovation. Companies can experiment, build extensions, and continuously evolve the system to match changing business dynamics. - Cost-Effectiveness

With no recurring license fees, open-source MRP software can be a more affordable option—especially for small and mid-sized manufacturers. It enables access to advanced capabilities without the financial burden of commercial licensing. - Community Support

A vibrant developer and user community often surrounds open-source solutions. These communities actively contribute updates, fix bugs, and offer forums and documentation—ensuring constant improvement and collaborative problem-solving.

Proprietary MRP Software

Below are some key strengths of proprietary MRP software.- Convenience and Simplicity

Proprietary software is typically ready out-of-the-box with pre-configured modules. This makes it a great choice for businesses that want a quick setup and don’t require much customization. - Dedicated Vendor Support

Users of proprietary MRP software benefit from structured vendor support, including onboarding, troubleshooting, and regular updates. This minimizes the need for in-house technical expertise. - Streamlined Implementation

Since proprietary platforms are built to deliver a standard set of capabilities, they are easier to deploy—often requiring less technical involvement during setup and integration.

The choice between open-source and proprietary MRP software ultimately depends on the unique needs, resources, and priorities of each manufacturing organization. Factors like customization flexibility, budget constraints, ease of deployment, and level of in-house technical expertise should all be weighed carefully. Regardless of the option chosen, a thoughtful evaluation of specific requirements will lead to the selection of the most suitable MRP software—one that not only streamlines manufacturing operations but also scales with your business and drives long-term growth.

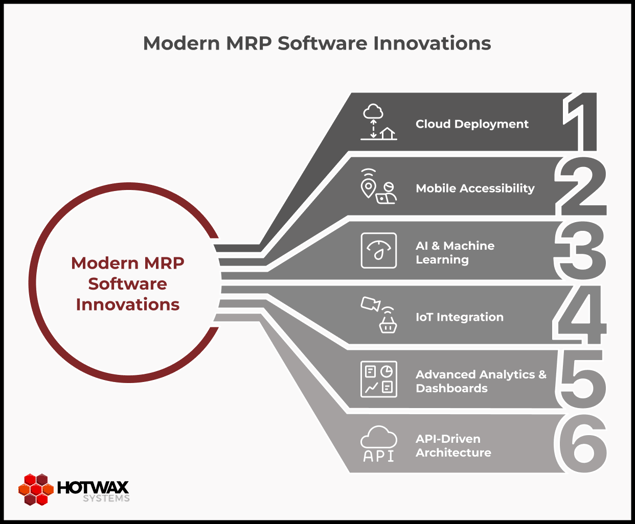

Modern Enhancements in MRP Software

Today's MRP software is not just about planning resources — it’s about smart automation, adaptability, and real-time decision-making. Here are the modern innovations that are reshaping MRP systems:- Cloud Deployment

Access MRP data anytime, from anywhere. Cloud-based solutions reduce infrastructure costs and improve collaboration across distributed teams. - Mobile Accessibility

Enable plant managers, warehouse teams, and procurement officers to view and act on real-time data using mobile apps and tablets. - AI & Machine Learning

Leverage predictive analytics to forecast demand, detect anomalies, and optimize procurement and production schedules automatically. - IoT Integration

Connect machines, tools, and sensors to your MRP system for real-time shop floor visibility and proactive equipment maintenance. - Advanced Analytics & Dashboards

Empower decision-makers with interactive dashboards, real-time KPIs, and scenario-based simulations for better planning. - API-Driven Architecture

Easily integrate with CRM, ERP, accounting, and other third-party systems to streamline data flow and reduce manual work.

Apache OFBiz® as MRP Software

While evaluating Manufacturing Resource Planning Software, one strong open-source option to consider is Apache OFBiz. Developed under the Apache Software Foundation, Apache OFBiz® provides a unified platform for supply chain management with inventory management at its core. It includes a wide range of modules that form the foundation for solutions such as manufacturing execution and planning, procurement management, order management, warehouse management, and more. These modules can be used individually or together to create a comprehensive solution tailored to a manufacturer’s needs.The MRP software in Apache OFBiz, part of the manufacturing module, features an intelligent material requirement planning engine that generates material requirement plans by considering sales orders, sales forecasts, production schedules, current inventory levels, and lead times. It also includes capabilities to track resource capacity, ensuring production planning aligns with actual machine and labor capacity. The software automates purchase requisitions, supports production monitoring, and streamlines shop floor control to improve visibility and minimize delays. As an open-source platform, Apache OFBiz allows businesses to customize and adapt the system for their unique business requirements and manufacturing workflows.

From MRP to MEPS: A Smarter Approach with HotWax Accelerator

For businesses looking to extend the capabilities of Apache OFBiz even further, one compelling option is the Manufacturing Execution and Planning System (MEPS) solution built using the HotWax Accelerator. The HotWax Accelerator is a pre-built, extensible framework built by HotWax Systems on top of Apache OFBiz, designed specifically to support complex manufacturing workflows. It enables companies to accelerate implementation while customizing the system to fit their exact operational needs.Apache OFBiz often falls short when it comes to delivering a modern, consumer-grade user experience, especially on mobile devices like tablets and phones. This is where the HotWax Accelerator offers a clear advantage by modernizing Apache OFBiz with advanced capabilities. It provides an intuitive user interface across devices, powerful enterprise search with Apache Solr, seamless real-time integration via Apache NiFi, and built-in analytics through Apache Superset. With its API-first architecture and high degree of customization, it transforms Apache OFBiz into a flexible, scalable, and insight-driven platform for today’s manufacturing needs. For industries such as Aviation, Aerospace, Defence & Space, Automotive Parts, Pharmaceuticals, FMCG, Fashion and Apparel Retail, the HotWax Accelerator provides basic building blocks to digitize and streamline both planning and execution processes.

Conclusion

Understanding the essentials of MRP software—its modules, features, and strategic benefits—is crucial before selecting the right solution for your manufacturing needs. A well-chosen MRP software not only streamlines material planning and production, but also supports smarter decision-making and long-term operational success.With a wide range of solutions available—from proprietary platforms to open-source options like Apache OFBiz—it’s important to assess what best fits your business processes, resource capacity, and customization needs. The right MRP software won’t just manage today’s operations—it will scale with your business and help you stay competitive in a dynamic manufacturing landscape.

HotWax Systems recommends the open-source Apache OFBiz framework for its comprehensive built-in modules and flexibility. Our expert team can help you customize it into a tailored MRP solution that fits your unique workflows and supply chain requirements. Connect with us today.